Recent years have seen increasing desire from brands to take more control over their product packaging design and manufacturing. Consumer trends and demands are contributing to this drive for change, whilst market challenges, like continued supply chain disruption, have also led to a drive from manufacturers for increased autonomy and flexibility.

As a result, manufacturers are looking at ways to customise more packaging within the factory walls and are turning to digital printing technology to make this a reality – a process known as ‘late-stage customisation’.

Late-stage customisation of product packaging on- or near- line using digital printing can provide new opportunities for brands, including enabling the creation of limited-edition packaging for special events, facilitating consumer engagement via on-pack marketing campaigns, and implementing personalisation to elevate the unboxing experience. Greater customisation of packaging in house can also allow manufacturers to maximise upstream productivity and mitigate supply chain delays.

In this blog, we will explore the advantages of late-stage customisation with digital printing.

What is late-stage customisation? What’s driving its popularity?

Late-stage customisation is any type of packaging printing or customisation performed by the manufacturer, as opposed to by a packaging provider or converter. Traditionally, this would have predominantly covered printing with information such as batch and product codes, and best before dates. However, more advanced in-line printing technology can now enable brands to buy in more generic packaging and add additional customisation within the factory walls, while still ensuring efficiency and cost-effectiveness.

James Orford, Product Manager at Domino’s Digital Printing Solutions, says: “During late-stage customisation, brand owners and converters can add or modify variable information almost before it is applied to the product. For example, one of our customers required their product’s ingredient summary to be translated into multiple languages. Rather than having to purchase and store a large quantity of stock in their warehouse for each language variant, they used one generic label. They added the variable data, in the form of multiple languages and SKUs, in the last stages of the production process.”

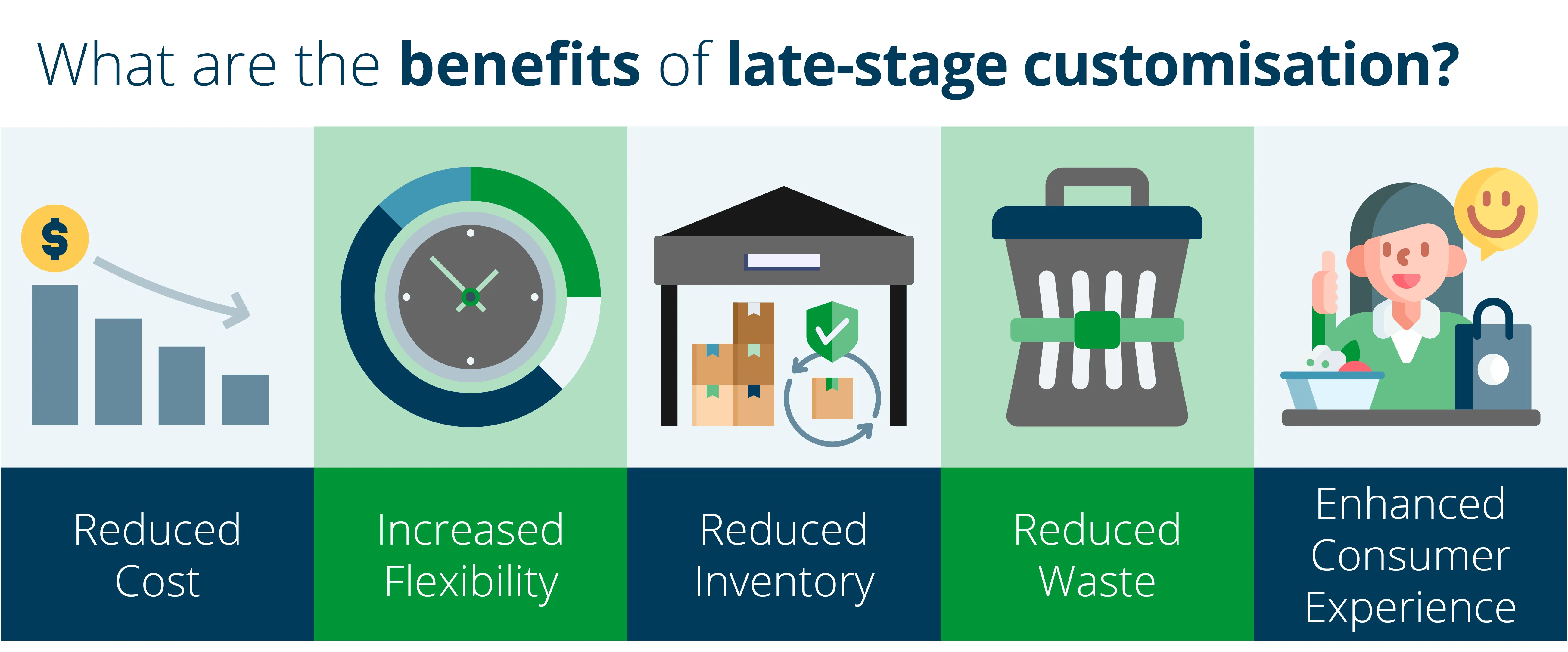

What are the benefits of late-stage customisation?

“Late-stage customisation holds many benefits for brands – in terms of increasingly factory efficiency and reducing the amount of stock and waste material in their supply chains and helping to expedite their products to market to meet evolving consumer demands,” says Orford. “It is becoming increasingly apparent to brand owners that taking more control over what is included on their product packaging using digital printing and late-stage customisation is crucial to remain competitive, productive, and flexible to change.”

Reduced costs: Late-stage customisation reduces brands reliance on external packaging providers, by providing the opportunity to trial new packaging designs and variations without having to adhere to minimum order runs, or additional costs for short-run prints.

Increased flexibility: Late-stage customisation gives brands more flexibility to respond quickly to changes in the marketplace. For example, if a brand wanted to test a new flavour based on consumer feedback or needed to adjust the ingredients list of a product due to a material shortage, late-stage customisation provides the capability to make the necessary changes to packaging in the in-factory rather than ordering new packaging stock. This has the added benefit of increased production uptime – with reduced lead times, and limited downtime due to product changeovers.

Reduced Inventory: Late-stage customisation minimises the need to store multiple packaging inventories because brands can buy in generic packaging and add customisation in line. Suppose a brand needs to create seasonal packaging; this can be planned, printed, and modified in-house using digital printing technology. As a result, less material is required to be printed in advance and stored in the warehouse – this can translate to significant cost savings, as packaging will typically have the greatest lead time of all material stock, and this can lead to it being the largest inventory item with low stock turnover compared to product ingredients.

Reduced waste: Buying large quantities of media for short runs to achieve minimum order quantities can be exceptionally wasteful, as often not all the stock will be used. This is not a problem with late-stage customisation using digital printing, as brands can produce their own short-run packaging in house, providing the capability to flex production without over-ordering.

Enhanced consumer experience: Brand owners understand the difficulty in standing out from the fierce competition on the supermarket shelf and are always looking for ways to interact with consumers. With late-stage customisation, brands can adjust packaging designs to enable greater consumer interaction. For example, in recent years, there has been significant interest in including variable 2D codes on product packaging, allowing brands to link to additional information, collect feedback, and further engage with consumers in store and at home.

Considerations for late-stage customisation

Late-stage customisation enables brand owners to have better control over their packaging content and to speed up the process of experimenting with new packaging designs. There are several potential scenarios where late-stage customisation could benefit brands, including:

New or experimental product launches: Creating multiple SKUs that correspond to various languages and multiple formats is a long process when launching a new product range. The artwork needs to be created in advance, and it can take up to twelve months to get the packaging design ready for the market. The time it takes for the product to reach the market can be reduced significantly by using digital printing and late-stage customisation.

Seasonal products: Keeping up with market trends is the key to making products attractive on the supermarket shelf and standing out from competitors’ products. With late-stage customisation, brands are better able to create engaging variations of product packaging – for example, packs decorated with bright colours for summer, with special product editions for Valentine’s Day and Christmas, or with a picture of a champion team for a sporting event – without relying on external packaging providers.

Security features: In the late-stage customisation process, it is possible to print variable data on labels or packaging that will allow track and trace of the product using unique codes. For example, high-end consumer goods can be protected against counterfeiting by applying variable data to 2D codes, such as QR codes, to allow consumers and supply chain partners to verify authenticity.

Regional language versions: Brand owners understand that engaging with their audience in their native language can establish a stronger emotional and cultural connection with their end user. Late-stage customisation allows for different language versions for each region, rather than printing multiple languages on one label. This frees up more on-pack space for branding and creative design. It also allows packaging to be modified to create special editions in regional languages.

Personalised packaging: The rise in ecommerce has increased the need to engage with the end-user in more personal and unique ways to stand out from the competition. Digital printing and late-stage customisation can provide new opportunities to include more personalised unboxing experiences. For example, creating packaging that speaks to the consumer on an individual level, with personalised packaging customised with consumer names, individual messages, or variable QR codes to collect consumer feedback.

“One of the main advantages of digital printing and late-stage customisation is that it is possible to create multiple packaging varieties, colours, and SKUs in record time and with minimal waste,” says Orford. “Late-stage customisation offers flexibility, which means brand owners can respond quickly to market demands without compromising their footprint. For example, by tracking how many QR codes are scanned, brand owners can determine which packaging is most successful and adjust their production accordingly. It also allows market expansion into additional regions using local languages without compromising creativity or minimalism in the packaging design. Last but not least, it offers better security, brand protection, and a more personalised packaging experience for consumers.’

Can late-stage customisation help your business?

The key to answering this question is to analyse your production lines. If your print runs have more than one product variety with different packaging colours, multiple SKUs, and variable data requirements, then the answer could be yes. When managing multiple, short run product lines, brand owners can significantly reduce cost, time, and waste by utilsing digital printing for late-stage customisation.

For more information about the benefits of digital printing to brand owners, please visit: https://www.domino-printing.com/en-in/products/digital-printing-products/digital-printing-products.aspx